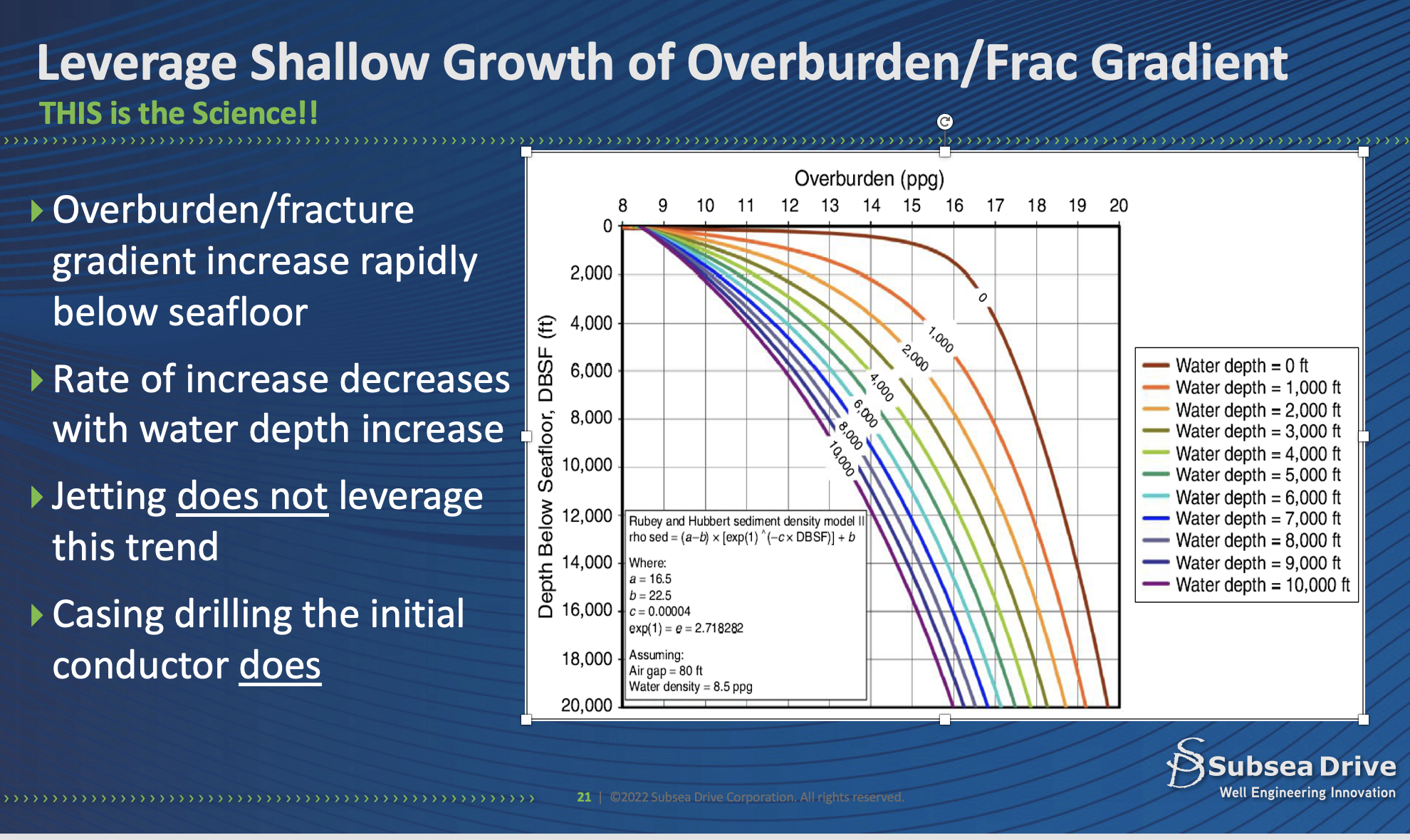

Deepening first string provides stronger casing shoe strength due to the rapidly increasing fracture gradients at shallow depths

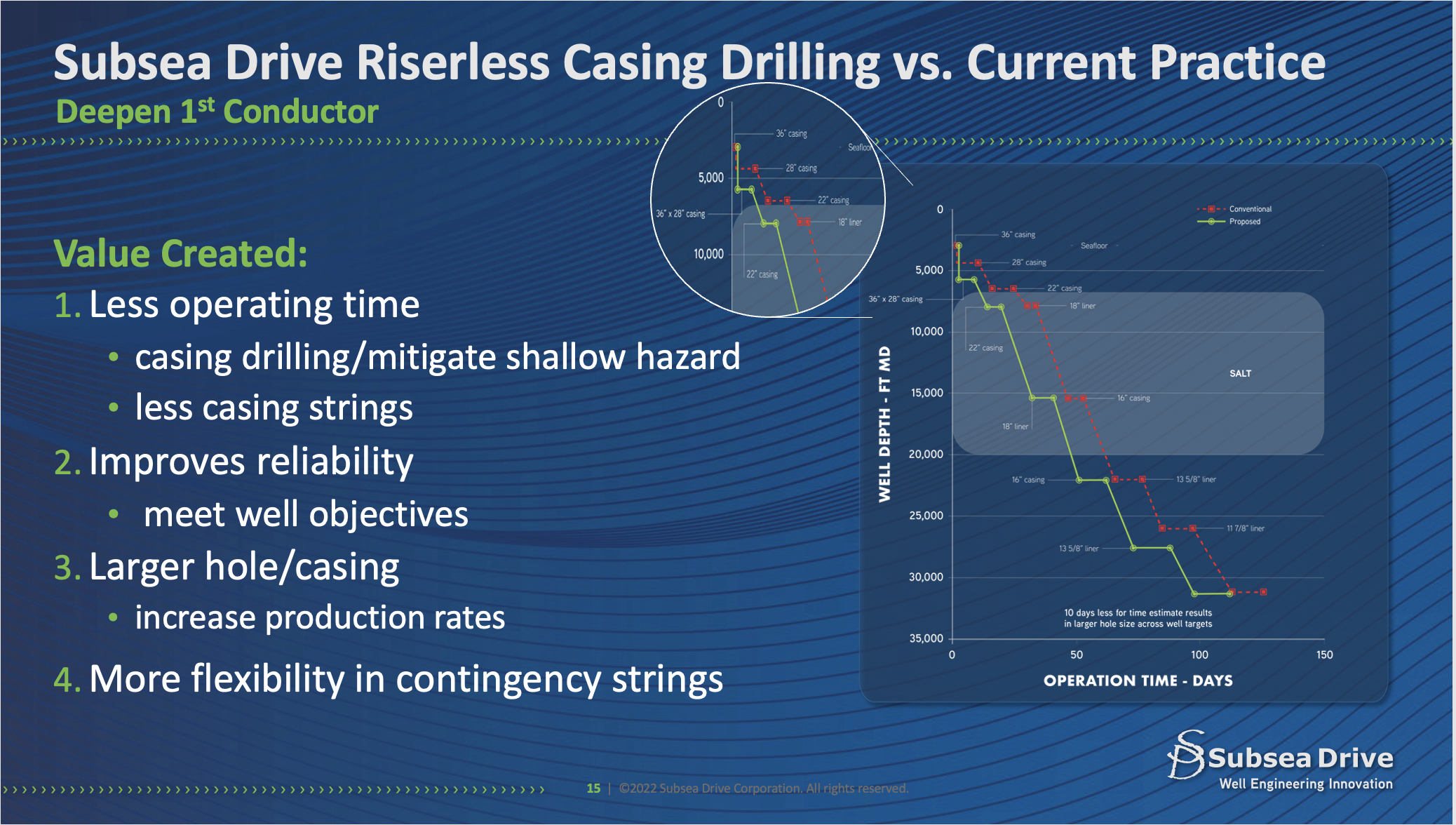

Deepwater Riserless Casing Seat Optimization is the basis for improving deepwater well reliability creating larger hole diameters below the high pressure wellhead conductor (HPWH).

The larger hole / casing annuli results in a ECD reduction to drill in the narrow operating pressure windows navigating the ballooning cycle.

Basic of Design

Base 1st casing setting depth on prevailing pore / fracture pressures

Drill to plan depth with casing drilling (replaces jetting & mitigates shallow hazards)

Drill next riserless section conventionally using “pump & dump”, or

Set HPWH with high pressure conductor deeper than conventional practice

U.S. Patent No.8,229,671 B2 July 24, 2012, Method and System for RiserlessCasing Seat Optimization